Ultrasonic particle manipulation

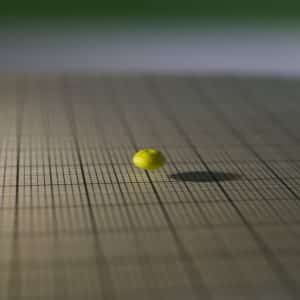

Ultrasonic particle manipulation is a non-contact manipulation method that uses ultrasonic waves to trap, orient and transport small particles. These particles can be various types of materials (plastics, metals, liquids), components (electronics components, micro-mechanical components), cells or other biological units.

URG is devoloping a 3D printing/assembly technology which uses ultrasonic particle manipulation. Ultrasonic particle manipulation has a few major advantages over mechanical handling of materials and components currently used in 3D printing/assembly processes:

- It can handle a wide range of materials and components with very different mechanical properties, shapes and sizes

- It complete avoids the parasitic electrostatic force, which makes it difficult to release small component when placing to a desired location

- Sensitive components can be manipulated without causing any damage

If the advantages of ultrasonic particle manipulation can be exploited in a 3D printing/assembly processes, more versatile printers can be created. Such printers would be capable of printing different materials and assembling various components, which means that in future whole electronic device could be printed with a single printer.

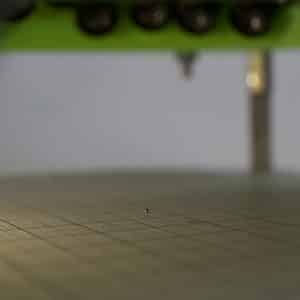

So far, the group has created a technology demonstrator that can assemble simple electronic circuits. The prototype uses an array of ultrasonic transducers for non-contact transportation and positioning of electronic components and a laser soldering of those components to a PCB board, also in a non-contact way. An on-board camera is used to coordinate the whole process, detect the PCB and component positions, calibrate the laser, etc. Watch the video below for more information on ultrasonic particle manipulation and the developed prototype.

Patents

Putkis, O., 2020, Contactless manipulation apparatus, assembly method and 3D printing, JP6655230B2.

Putkis, O., 2017, Contactless manipulation apparatus, assembly method and 3D printing, LT6438B.